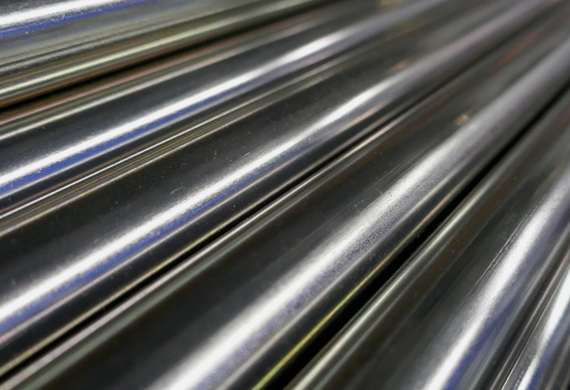

Centreless bar turning process removes scale, surface defects amd surface decarburisation, aiding subsequent operations, without signficantly changing the elastic limits or work hardening material.

For engineers, centreless bar turning provides the opportunity to commence production from bar stock at the optimum diameter, saving machining costs and material wastage.

For the stockholder, centreless bar turning provides the opportunity to convert one stock size to a variety of other sizes including hexagonal and octagonal sections to rounds.

The process also offers both the engineer and the stockholder the possibility of recovering surface damaged material, as well as surplus or obsolete stock.